| Programa | Concepto subvencionable | Organismo | Expediente | Importe Subvencionable | Duración |

|---|---|---|---|---|---|

| AYUDAS A LAS ACTUACIONES DE EFICIENCIA ENERGÉTICA EN PYMES Y GRANDES EMPRESAS DEL SECTOR INDUSTRIAL | REESTRUCTURACION DE HORNOS DE FORJA Y TRATAMIENTO PARA LA RECUPERACIÓN DE CALOR RESIDUAL | GOBIERNO VASCO | 441-AEE/2019 | 25.760,36 € | 2023-2024 |

| HAZITEK | PROYECTOS I+D (S420NL) | GOBIERNO VASCO | ZL-2024/00115 | 45.771,19 € | 2024 |

| HAZITEK | PROYECTOS I+D (S420NL) | GOBIERNO VASCO | ZL-2023/00050 | 55.189,68 € | 2023 |

| HAZITEK | PROYECTOS I+D (BRD + 6,5 +) | GOBIERNO VASCO | ZL-2022/00094 | 40.780,66 € | 2022 |

| HAZITEK | PROYECTOS I+D (S420NL) | GOBIERNO VASCO | ZL-2022/00667 | 59.427,21 € | 2022 |

| HAZITEK | PROYECTOS I+D (BRID+6,5) PLUS | GOBIERNO VASCO | ZL-2021/00287 | 53.101€ | 2021 |

| HAZITEK | PROYECTOS I+D (BRID+6,5) | GOBIERNO VASCO | ZL-2020/00103 | 84.447€ | 2020 |

| HAZITEK | PROYECTOS I+D (BRID+6,5) | GOBIERNO VASCO | ZL-2019/00705 | 62.802€ | 2019 |

| HAZITEK | PROYECTOS I+D (BLOOMPRO) | GOBIERNO VASCO | ZE-2018/0002 | 48.097€ | 2018-2019 |

| IDAE | INVERSIÓN EN QUEMADORES REGENERATIVOS DE GAS | MINISTERO DE INDUSTRIA, COMERCIO Y TURISMO | FN-PGESI-2018-001631 | 192.720€ | 2018-2019 |

| REINDUSTRIALIZACIÓN Y FOMENTO DE LA COMPETITIVIDAD 2015 | INVERSIÓN EN INCREMENTO DE LA CAPACIDAD INDUSTRIAL Y DESARROLLO DE NUEVOS PRODUCTOS | MINISTERO DE INDUSTRIA, COMERCIO Y TURISMO | RCI-090000-2015-1 | 5.000.000€ | 2015 |

| AYUDAS A LAS ACTUACIONES DE EFICIENCIA ENERGÉTICA EN PYMES Y GRANDES EMPRESAS DEL SECTOR INDUSTRIAL | SISTEMA DE RECUPERACIÓN DE CALOR RESIDUAL EN HORNOS DE FORJA | GOBIERNO VASCO | 165-AEE/2019 | 25.500 € | 2020 |

News

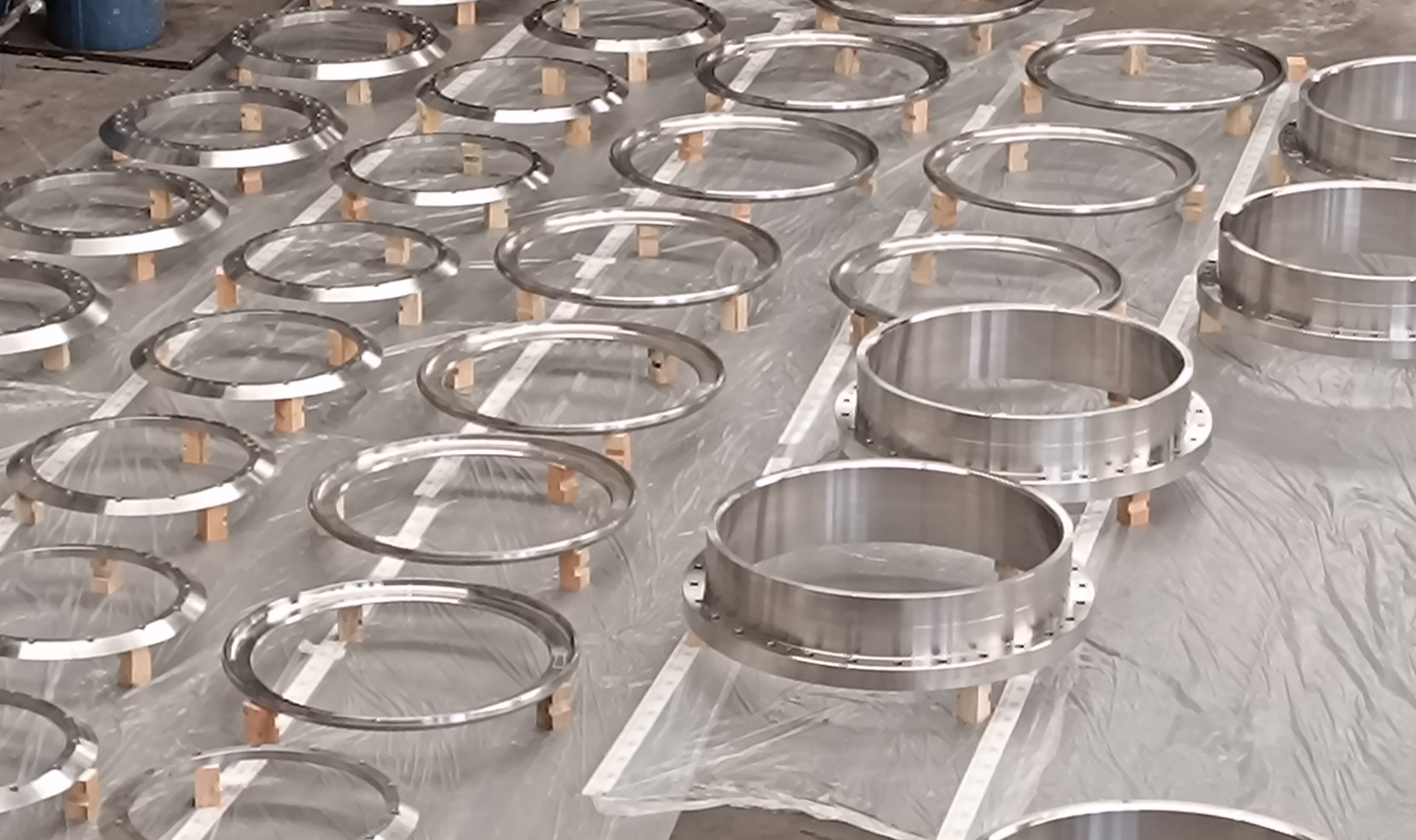

Euskalforging, new Milestone achieved, Baltyk 2 & 3 project delivered in record time.

- Details

euskalforging new Milestone achieved: Picture of the last shipment that completes the delivery of 300 flanges ranging from Ø 7.500 to 7.800 mm for Transition Pieces & Monopiles, meaning 100% of the supply for the Baltyk 2 & 3 offshore wind farm, a 1.44 GW project size & €6 billion investment.

EUSKALFORGING, the future is TODAY

- Details

euskalforging has successfully completed the Expansion Plan at its Sestao plant, a project that has been two years in the making.

Thank you to Euskalforging shareholders, team and all companies participating in the Project to make it happen. In line with the company’s distinctive “stamp”, we are now ready to supply XXXL ring sizes and weights, incorporating innovative solutions. Further details will be shared in dedicated meetings.

Euskalforging in the forefront, pushing green energy in every kind

- Details

euskalforging selected to supply key components for the most powerful Hydro Plant in Colombia, GUAVIO.

GUAVIO supplies daily 8% of the energy consumed in the country. The components supplied are made in a special and resistant steel grade of most superior quality, more details are confidential. Thanks for the confidence in Euskalforging.

Euskalforging increases its leadership by winning the largest wind farm in Europe

- Details

euskalforging will ring roll a total of 300 flanges for MP/TP foundations for the Baltyk 2 & 3 offshore wind farm, for Equinor and Polenergia. The flanges will be supplied to SIF, which will complete the fabrication of the wind turbine foundations, both 100 Monopiles and 100 Transition Pieces.

Euskalforging keeps growing its offshore wind park portfolio: now with WINDANKER

- Details

Euskalforging has been awarded with the production of flanges for Windanker, the third offshore wind park that Iberdrola is developing in the Baltic. Windanker will be located in German waters and once it is commissioned in 2026, it will have 315 MW capacity.